New Life For An Old Athearn Box Car

You find them sometimes at meets and train shows. They are usually hidden in a box under the sales table. Often missing parts or suffering damage, they are the ‘junkers’. They sell cheap – or sometimes are just given away. To somebody who’s a champion of sorts for lost model building causes, they can be a rewarding challenge.

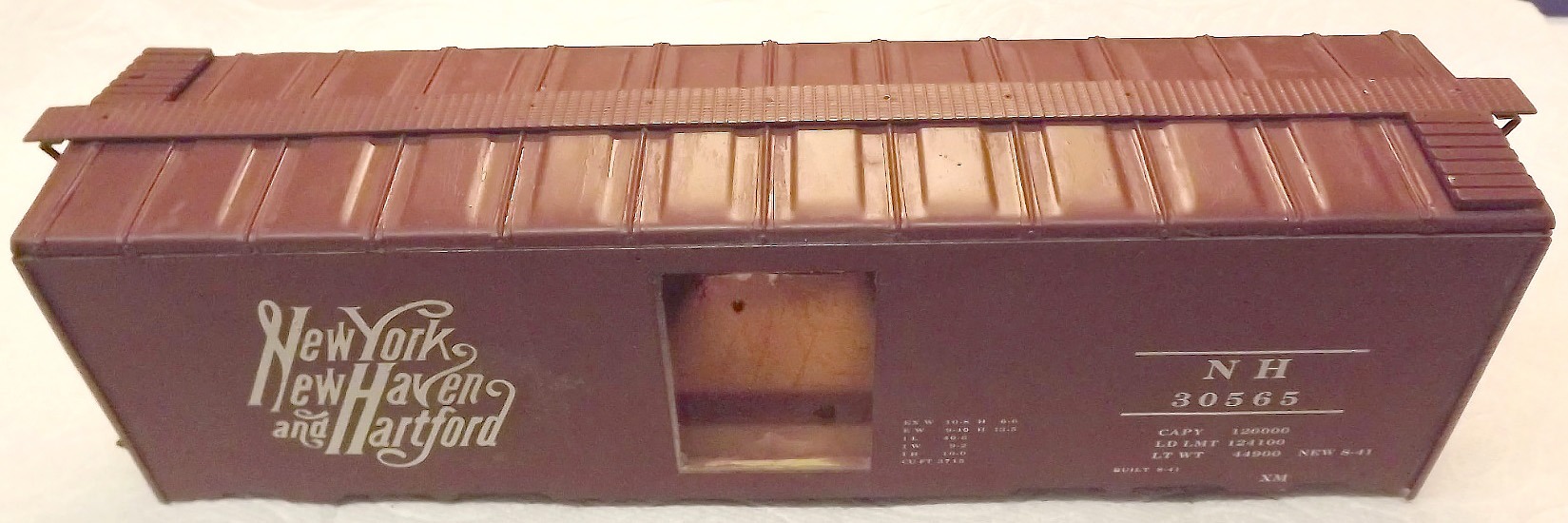

The subject is an Athearn New Haven box car, built in 1947 from an early issue (possibly pre-WW II) kit. In 1947, the Athearn kit for a box car like this one sold for $6.00, including trucks. Sounds cheap, eh? Well, that would be $68.00 in 2019 money! And, you still had to build it.

The New Haven, struggling through the Great Depression with outdated 36’ wood body boxcars, bought 500 of its first new, steel 40’, 60-ton capacity box cars in 1941. A 60-ton nominal rating was unusual. Most new 40’ steel boxcars had a 50-ton rating.

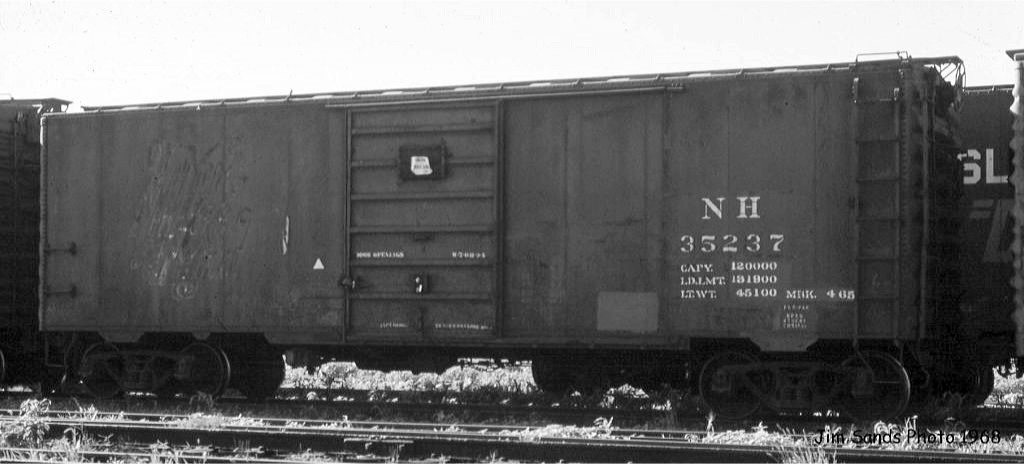

This one still rated for 60 tons somehow escaped a Patrick McGinnis era repainting. It carries an original big, but faded “New York, New Haven and Hartford” script herald in 1965. The paneled 8’ wide doors on NH 35237 below are replacements. The originals were 6’ wide doors of a corrugated “Youngstown” design.

Admittedly, the Athearn model is not super-accurate for the prototype. Most kits of the time were close but not exactly perfect in that way. Still, it can be a creditable looking model when finished.

Here is an Athearn New Haven box car body found for free. In all, it does not look bad. The sides are in good condition considering their age. Yet the model lacks trucks, couplers, doors, door guides, side ladders and a few other details. Curiously it has Walthers cast metal roof corner platforms, with Athearn’s then-new embossed aluminum Blaw-Knox running board. The original matching corner platforms may have been lost.

Underneath is the older Athearn stamped metal (tinplated can stock) underframe. It was also used in period Grace Line car kits, which had pressed, plasticized card stock sides, ends and roof panels.

Threaded bushings for the truck king pin screws were soldered in place on the center sill, as were the cross bearers. The under frame is held to the car body with two small bolts located in the center sill, behind the truck posts. Pins hold the ends of the cross bearers to the car floor, keeping them parallel. Later Athearn under frames had stamped parts with sharper definition. But here, the less defined originals from 1947 were kept. The three-piece air brake parts were also kept and relocated to prototypical positions.

Step One in any rebuild involves taking it apart for ‘re-kitting’. This reveals the condition of unseen parts which might need replacement. It also makes it easier to repair and recondition other parts. In this case, un-needed and over-sized holes in the stamped brass car ends were repaired with solder and filing. Automotive spot putty filled and smoothed small dents and creases.

The car sides were in very good condition and nicely lettered. Note the “NEW” date, which is also accurate for that New Haven number series. However, a later weigh station code and date would be better, as cars were re-weighed on regular basis as time passed (losing weight) and repairs made (gaining weight).

While the wood ends and roof suffered some gaping holes from previous assembly with small nails, they were filled with Plastic Wood and sanded smooth again.

The interior was detailed by drawing in side sheathing board seams and interior reporting marks. They were most important when loading cars on parallel tracks at large terminals where the outside of a car might not be seen.

The car ends are marked so the sides will go back to their original positions on reassembly. The “A” end of a freight car is the front and “B” is the back, or hand brake end. That also determines which side of the car is right or left. it’s another important thing to note when loading or unloading a car or when making repairs.

The original wood floor had become brittle with age and had splits in it from the many nails used to hold the floor and ends together. A new floor was made with sheet bass wood overlaid with Micro Scale 1/8” decking for the bottom side and a thin wood, laser cut and detailed interior floor top for an Intermountain box car. The new floor was made to match the thickness of the original floor for a correct fit.

The car body was put back together, matching the parts for squareness. Walthers GOO with a few short finishing nails hold the floor to the car ends. Only two at each end were used. The original builder had eight nails in each end – four through floor to the car end and four through the end to the floor. The roof, aside from extra seam caps (ribs) on each end and some small dents to be filled, was otherwise in good shape.

The wood inner car sides were glued in place. Once set, the metal car sides were pinned on over them. This included installing replacement stamped metal door guides. The car ends followed, slipping the top edge under the roof cap and checking how the end corners met the car sides. A gap of almost 1/16” was found. So, the glued and pinned-on sides came off. Thin styrene strips were glued around the body edges to shim them outward. With that, the re-installed sides fitted snug within the car end corners.

The underside of a prototype box car floor was not painted, since it was installed after the frame was completely assembled, painted and the car body built upon it. Also, boxcar flooring (and interior sheathing) was replaced as needed from wear and tear or age. Here was the chance to model the paint-less wood flooring of the underside.

The under frame has added details for longitudinal stringers, secondary cross braces and corner diagonal braces using painted, styrene strips. An air brake pipe made with .040” diameter brass rod was added after drilling holes for it through the center sill and cross braces. Full brake piping and rigging could be added later.

Air brake hoses on the model are from BTS. Newer Athearn Delrin “Bettendorf” trucks with metal wheels were installed. Kadee 745 couplers were put on and the uncoupling rods were made so they could be easily removed for any needed work later, such as replacing the centering springs in the coupler draft gear boxes.

On early Athearn kits, stand-off brackets were provided for the car side and end grab irons. No longer offered after WW-II, these brackets held grab irons with flattened ends and holes for pining them to the car.

Missing corner steps (stirrups) were replaced. Athearn made them with long ends having two holes at each end. The upper hole is used when pinning on a side ladder with the corner step. The lower hole is used for the left corner step of the car as shown, with the upper hole clipped off.

The missing side ladders were replaced with ladders matching the rung spacing of those on the car ends. It’s helpful in projects like these to a have a stash of old parts collected along the way or salvaged from totally scrapped models. New end grab irons were made with .025” diameter brass rod. Sometimes Athearn parts can still be found at train shows since that line of kits and parts continued into the 2000’s through Pacific HO, Locomotive Workshop, Old Pullman and most recent but last (2006?), “Box Car Jim” Watson.

The roof was detailed with built up wood running board and end platforms made with 1/32” x 1 /8” strip wood. Prototype New Haven box cars built before WW-II were delivered with wood running boards and platforms. They got replacement metal roof fittings by the mid-1950’s.

In the post-war years, New Haven took delivery of more steel 40’ box cars. These and others had their doors painted black. The doors on this model are from another older Athearn car on which the Youngstown doors were replaced with panel doors. So, they were painted black and put on this model.

The car ends and roof were repainted with Scale Coat No. 2 box car red, which reasonably matched the original Ahearn sides. It took two sprays of Dull Coat to tone down the paint’s high gloss.

End details added include the handbrake chain and rod fitted with a clevis for the bell crank (cut from a scrap of .030” aluminum) and a retainer line which is made from .019” diameter brass rod. End lettering was done with a Walthers alphabet set and parts of a Champ decals box car data set.

Here is the 72 YO Athearn New Haven 30565, all set for a renewed life in O scale service. Also added are the small identifying ‘R’ and ‘L’ by the lower left corner of the door on each side.